Advantages of OEM Part Digital Manufacturing

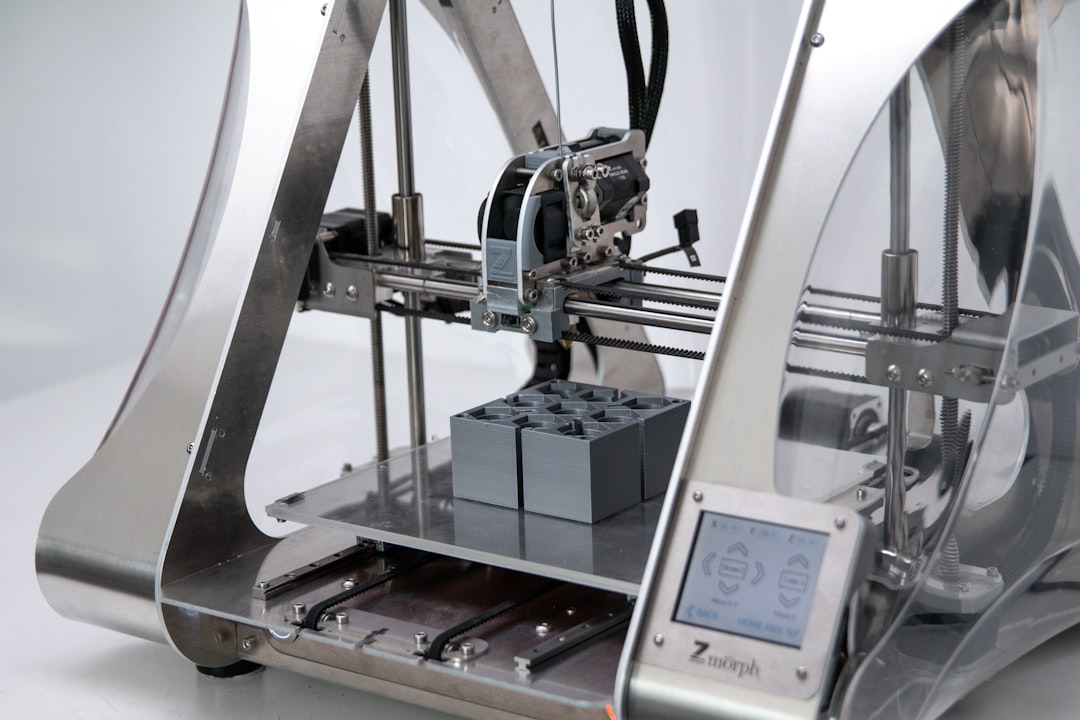

OEM part digital manufacturing is the use of 3D printing and additive manufacturing technologies to make spare parts. These processes create three-dimensional parts from computer-aided design (CAD) models by successively adding material layer by layer until a physical part is created.

Whether the part is produced by an on-demand manufacturing firm, or by an OEM or third party, these methods offer several benefits for companies that produce or use spare parts.

Digitization, for example, can help reduce the number of errors that occur during spare parts production. It also allows for more efficient communication between the manufacturer and the company that uses the spare part, so that the parts are delivered on time and in a high-quality state.

Digital supply chains empower manufacturers to quickly identify and respond to capacity issues or distressed suppliers that threaten supply chain performance. This ability to rapidly monitor and manage supplier capabilities improves the quality of the products that they manufacture.

It can also give manufacturers at this homepage the capability to better track and manage customer orders, which can be useful in ensuring that they have adequate quantities of products available at all times to satisfy demand.

Aside from being a more efficient way to produce and deliver spare parts, OEM part digital manufacturing can also save companies time and money. As a result, it can be an attractive option for both small and large businesses.

The key to OEM part digital manufacturing at https://syncfab.com/3d-printing-services/ is the ability to connect with customers and supply partners across a network of devices. This can be done through software and internet-of-things (IoT) technology.

In addition, OEM part digital manufacturing can provide a means to ensure that the product that is delivered matches the original model. This can be important to the success of the product, as well as to help prevent issues that may arise from improperly shaped or designed parts.

For companies that rely on third parties for their spare parts, this can be particularly difficult. They often face delays in receiving manufactured parts, due to increased demand or production downtime. In addition, minimum order quantities are often imposed. Get more insights about printing at https://www.britannica.com/technology/3D-printing/images-videos.

Fortunately, this can be overcome by using digital warehousing to maintain a current inventory of spare parts. This can be done through a simple online storage platform or by developing a more sophisticated solution.

Digital warehousing can also be used to help with the process of reverse engineering, which is when an old spare part is scanned and re-created using new technology or materials. This can be done with 3D scanning and CAD or by using digital fabrication tools.

It can also be used to improve the quality of spare parts by ensuring that they are made from proper materials, and in the correct manner. This can be achieved by using DFM analysis that helps to reconcile deviations between the design model and how the parts will be made in the manufacturing process.

Despite these advantages, there are still many barriers that companies need to overcome in order to achieve this goal. These include identifying the right technologies and strategies to implement, as well as developing strong partnerships with the companies that will benefit from this type of spare part production.